What is a cardboard shipping box and how to use it?

Cardboard shipping boxes play a crucial role in the logistics industry. In a 2021 report, the demand for these boxes was projected to reach 92 million tons globally by 2025. They are favored for their lightweight nature and sustainability. Approximately 70% of all shipped goods utilize cardboard packaging today.

Using cardboard shipping boxes effectively requires understanding their features. These boxes come in various sizes and strengths, accommodating different products. For instance, double-wall boxes provide extra protection for fragile items. However, sometimes businesses neglect to choose the right box size, leading to product damage during transit.

The environmental impact of cardboard shipping boxes is significant. While they are recyclable, improper disposal can harm ecosystems. Companies should be mindful of their sourcing practices and strive for sustainability. The balance between cost efficiency and environmental responsibility remains a challenge in the industry. Taking these factors into account is essential for effective shipping strategies.

What is a Cardboard Shipping Box?

A cardboard shipping box is a versatile packaging solution designed for transporting goods. Unlike traditional boxes, these are often made from recycled materials, making them environmentally friendly. They come in various sizes, shapes, and strengths, allowing for a wide range of uses. A well-structured cardboard box provides protection against impacts and external elements during shipping. This is essential for ensuring items arrive in good condition.

While a cardboard shipping box is easy to use, improper packing can lead to problems. It’s crucial to select the right size box. A box that is too large can result in excessive movement, causing damage. On the other hand, a box that is too small may crush or break the items within. Adding cushioning materials, such as bubble wrap or packing peanuts, can help stabilize the contents.

Some people rush through the packing process. They forget to tape the box securely or neglect to label it properly. This oversight can create issues during shipping and delivery. Reflecting on these points can help improve the packing experience. Each time you use a cardboard shipping box, consider how you can enhance your approach.

What is a Cardboard Shipping Box?

| Dimension | Description | Usage | Material Type |

|---|---|---|---|

| Small | Typically used for shipping small items like books or electronics. | Personal shipping, e-commerce, and gifts. | Single-wall cardboard. |

| Medium | Ideal for medium-sized items such as clothing or kitchen goods. | Retail and online businesses. | Double-wall cardboard. |

| Large | Used for bulky items such as furniture or large appliances. | Furniture stores and manufacturers. | Triple-wall cardboard. |

| Custom | Tailored to fit specific items or unique shapes. | Specialty shipping and promotional items. | Varied materials based on requirements. |

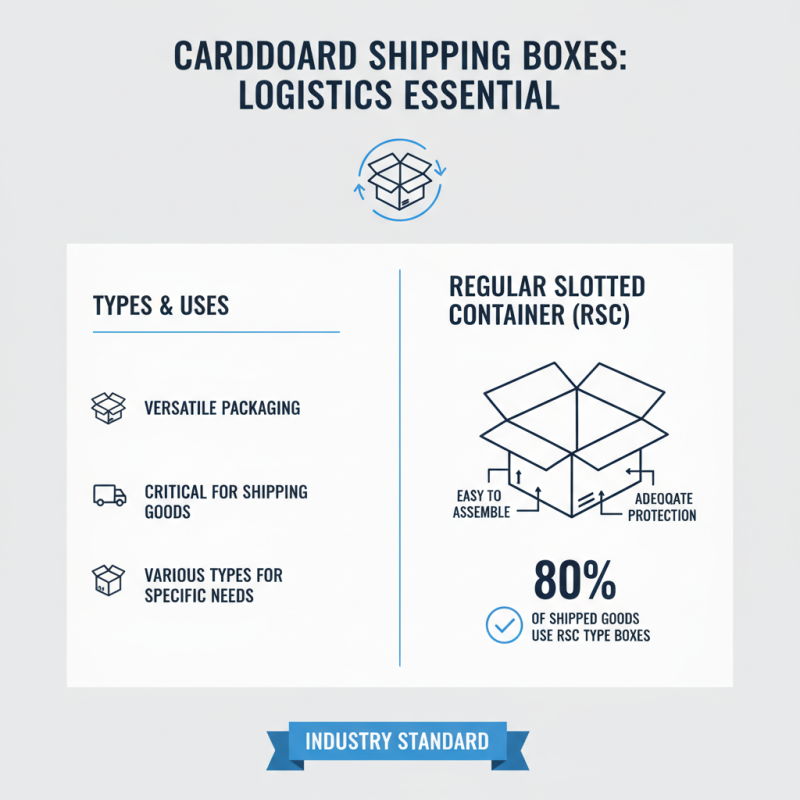

Types of Cardboard Shipping Boxes Available

Cardboard shipping boxes are essential in logistics. They come in various types, each suited for specific needs. One common type is the regular slotted container (RSC). RSCs are versatile and easy to assemble. They are widely used because they provide adequate protection for items during transit. According to industry reports, around 80% of shipped goods utilize this type of box.

Another option is the die-cut box. These boxes are custom-shaped to fit unique products. They help minimize movement inside the box, reducing damage risk. The global cardboard box market is projected to reach USD 112 billion by 2025. With such demand, understanding box types is crucial for effective shipping.

There are also heavy-duty boxes for larger and heavier items. They are reinforced and can carry more weight. Companies often use these boxes for machinery or industrial equipment. Despite their advantages, some businesses overlook proper sizing. Incorrect box sizes can lead to increased shipping costs. It’s a detail that requires careful consideration.

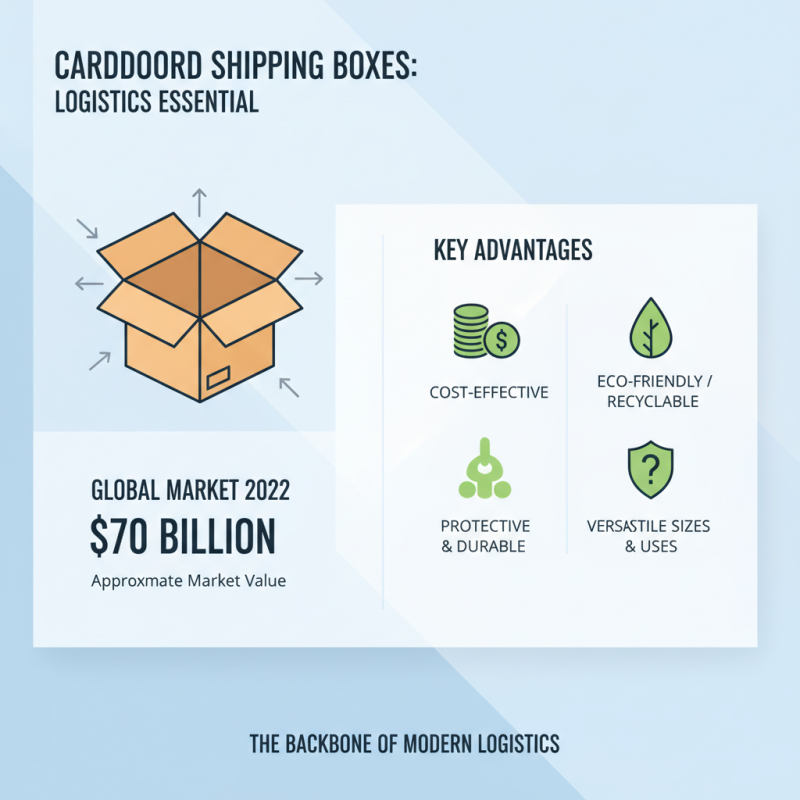

Benefits of Using Cardboard Shipping Boxes

Cardboard shipping boxes are essential in the logistics industry. They provide a cost-effective solution for transporting goods. In 2022, the global cardboard box market reached approximately $70 billion, indicating a strong reliance on this material. The advantages of using cardboard shipping boxes are significant and varied.

One major benefit is their lightweight nature. Lighter packages reduce shipping costs. This factor is crucial, as shipping expenses often account for a large portion of sales. According to industry studies, a 1% reduction in weight can lead to cost savings of up to 15% in logistics. Additionally, cardboard boxes are recyclable. This aspect aligns with growing consumer demand for sustainable practices. The recycling rate for cardboard is about 89.5%, emphasizing its environmental benefits.

However, cardboard boxes can also pose challenges. They are not waterproof and may weaken when exposed to moisture. This limitation can lead to damaged products. Companies must consider their shipping conditions carefully. Nonetheless, cardboard boxes remain a popular choice due to their adaptability and affordability.

Steps to Properly Pack Items in a Cardboard Shipping Box

Packing items properly in a cardboard shipping box is essential. The right techniques can prevent damage during transit. According to a recent industry report, around 30% of items shipped suffer from damage due to improper packing. This statistic highlights the need for careful consideration when preparing shipments.

Start by choosing the right box size. A box that’s too big allows items to move around. This can lead to breakage. Fill any gaps with packing materials, like bubble wrap or crumpled paper. This added support keeps items snug and secure. Ensure the box is strong enough for the weight. A weaker box can collapse, causing loss.

When sealing the box, use high-quality tape. Make at least three strips along the seams. This minimizes the risk of openings during transport. Despite these precautions, mistakes can happen. Sometimes, people overlook fragile items. Labeling boxes clearly can help identify what's inside, reducing potential mishaps. Always reflect on your packing process. Improvement is possible and learning from past errors is key.

Best Practices for Sealing and Labeling Shipping Boxes

When shipping items, sealing and labeling are crucial steps.

A well-sealed box prevents damage during transit. Poor sealing can lead to lost items. Use quality packing tape to secure the flaps. Apply several strips for extra strength. Avoid flimsy tape that might peel off.

Labeling is equally important.

Clear labels help ensure packages reach the correct destination.

Use a permanent marker or print labels. Include both sender and recipient addresses. Don't forget to add contact information. A missing address can cause delays or returns.

It’s easy to overlook packaging details. Rushed packing results in mistakes. Take your time to double-check everything. Check seals, labels, and box condition thoroughly. A small oversight can lead to major hassles later. The process requires attention to detail and care.

Related Posts

-

Top Custom Shipping Boxes Ideas to Enhance Your Packaging Experience

-

Top 10 Benefits of Using Corrugated Boxes for Shipping and Storage

-

Why Custom Made Boxes Are Essential for Your Packaging Needs

-

What are Custom Mailer Boxes and How Can They Benefit Your Business?

-

How to Choose the Best Cardboard Boxes for Your Shipping Needs

-

How to Create Personalized Shipping Boxes for Your Business Essentials?