2026 How to Choose Custom Size Shipping Boxes for Your Business Needs?

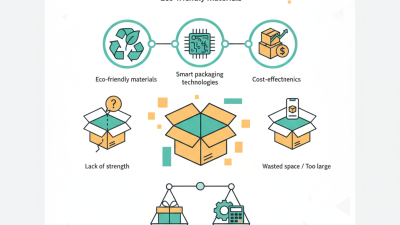

Choosing the right **custom size shipping boxes** is essential for any business aiming to optimize logistics and customer satisfaction. According to recent industry reports, about 30% of shipping costs arise from poorly sized boxes. When boxes are too big, additional void fill is needed. This results in increased shipping expenses. On the other hand, boxes that are too small can lead to product damage, causing dissatisfaction and returns.

In 2023, a survey indicated that 65% of consumers prefer brands that utilize eco-friendly packaging. Custom size shipping boxes allow businesses to enhance their sustainability efforts by minimizing waste. These tailored solutions ensure that products fit snugly, reducing the overall environmental footprint. However, many businesses struggle to balance cost and efficiency when choosing their packaging.

Reflecting on these challenges, it's clear that choosing the right **custom size shipping boxes** requires careful analysis. Some businesses still rely on standard sizes, despite the potential for wasted resources. Adopting a customized approach not only improves shipping performance but also impacts customer loyalty in a competitive market. It's a decision too important to overlook.

Understanding the Importance of Custom Size Shipping Boxes

Custom size shipping boxes play a crucial role in the success of any business. According to a report from IBISWorld, companies lose nearly $80 billion annually due to inadequate packaging. Standard boxes often lead to damaged products, wasted space, and increased shipping costs. Custom boxes fit products perfectly, reduce movement during transit, and enhance customer satisfaction.

Choosing the right box size can significantly affect operational efficiency. For example, using the right dimension can lower shipping expenses by up to 30%. It also minimizes the need for extra packing materials, such as bubble wrap or foam peanuts.

**Tips:** Remember to measure your products accurately. Overly large boxes can lead to damage and higher shipping fees. Take into account the weight of the items, as heavier products require sturdier boxes.

Custom boxes also present an opportunity for branding. When customers receive a well-fitted, attractive package, it enhances their unboxing experience. Research shows that 72% of consumers say packaging design influences their purchasing decisions.

**Tips:** Don't overlook the aesthetics of your box. A branded box can leave a lasting impression. Evaluate your packaging regularly to adapt to changing market demands and product lines. This will help you stay competitive and responsive.

Identifying Your Business's Specific Shipping Requirements

When choosing custom size shipping boxes, it's crucial to identify specific shipping requirements for your business. Understand the types of products you ship. Are they fragile or bulky? Measuring the dimensions of your items can provide clarity. This will help avoid excessive space or damage during transit.

**Tip:** Consider the weight of your products. Heavier items may need sturdier materials. Assessing weight distribution is key too. Boxes that are too large might lead to shifts during delivery.

Also, think about your packaging process. Will your team pack quickly? Custom boxes can streamline this. Just remember, there can be a trial and error phase. Not all sizes will fit every shipment perfectly. Reflect on past experiences to guide your choices. Adjust as necessary for improvements.

**Tip:** Test out a few box sizes before making a bulk order. This can save time and money. Careful planning now can lead to smoother shipping later.

2026 Custom Size Shipping Boxes for Your Business Needs

This chart illustrates the number of orders for different sizes of custom shipping boxes required by businesses in 2026. The data indicates the demand for small, medium, large, extra large, and customized shipping boxes.

Factors to Consider When Selecting Box Sizes

When selecting box sizes for shipping, various factors demand attention. One crucial aspect is product dimensions. A 2022 industry study shows that 45% of shipping-related costs stem from packaging. Oversized boxes increase shipping fees and waste materials. Measuring your products accurately is essential. Strive for a snug fit that ensures safety without excess space.

Another factor is the destination and shipping method. Items sent via air may require different sizes than those sent by ground. Consider regional shipping trends. Studies indicate that 60% of customers prioritize sustainable packaging. Custom-sized boxes can reduce material waste, aligning with eco-conscious consumers. Adjustable boxes could also cater to varied product sizes. Balancing these elements is challenging yet crucial.

Lastly, assess your storage capabilities. Custom boxes may save space but require careful planning. Tight storage areas may complicate inventory management. Regular reviews of box size effectiveness ensure your shipping strategy remains efficient. Analyze customer feedback and shipping costs periodically for potential improvements.

2026 How to Choose Custom Size Shipping Boxes for Your Business Needs? - Factors to Consider When Selecting Box Sizes

| Box Type | Dimensions (L x W x H) | Weight Capacity (lbs) | Ideal Use | Material Type |

|---|---|---|---|---|

| Regular Slotted Container (RSC) | 12 x 12 x 12 inches | 30 lbs | General shipping | Corrugated cardboard |

| Die-Cut Box | 16 x 10 x 4 inches | 20 lbs | Retail packaging | Cardboard |

| Mailer Box | 10 x 8 x 2 inches | 15 lbs | E-commerce shipping | Rigid cardboard |

| Full Overlap Box | 24 x 18 x 12 inches | 50 lbs | Heavy items | Double-wall corrugated |

| Plastic Shipping Box | 20 x 15 x 10 inches | 40 lbs | Moisture-prone items | Plastic |

Exploring Material Options for Shipping Boxes

When selecting shipping boxes for your business, the material plays a crucial role. There are typically three main options: corrugated cardboard, rigid boxes, and polyethylene packaging. Corrugated cardboard is cost-effective and widely used. It's lightweight yet sturdy, making it ideal for various goods. Rigid boxes, on the other hand, offer more protection, so they are preferred for fragile items. Polyethylene packaging is waterproof and great for protection against moisture.

Tips: Consider your product's fragility. If your item is delicate, choose a more robust material. Also, think about the shipping duration. Longer transit times may require better protection.

Look at the environmental impact too. Many materials can be recycled, which is essential for a sustainable approach. Not all cardboard is created equal. Some may not hold up well in damp environments. This could lead to damages that affect your brand’s reputation. Be mindful of that.

Tips: Always test your packaging. Send a few samples with your products. Gather feedback on the materials. Is it easy to open? Does it feel secure? Use this information to improve. The right material can make a significant difference in customer satisfaction.

Cost Considerations for Custom Shipping Solutions

Choosing the right custom size shipping boxes is essential for businesses. Cost considerations play a significant role in this process. Begin by assessing the average dimensions of your products. Measuring accurately will help reduce extra material costs. Remember, oversized boxes can lead to increased shipping fees.

Tip: Always compare quotes from different suppliers. Some may charge higher for custom sizes. Investigate options for bulk orders to help with pricing.

Another aspect to consider is the thickness of the box material. Thinner materials may save money, but they can compromise the safety of products during shipping. Choose a balance between cost and quality.

Tip: Prototype your packaging to test durability before making bulk purchases. This could save future costs. Look out for hidden fees in shipping contracts. They can add up quickly. Adjust your packaging choices based on cost analyses to ensure your business remains profitable.

Related Posts

-

2025 How to Choose Custom Printed Boxes for Your Business Needs

-

Why Custom Printed Mailer Boxes Are Essential for Your Business Success

-

2026 Top Custom Shipping Boxes Innovations for Your Business Needs?

-

2026 Best Shipping Boxes for Your Packaging Needs?

-

How to Choose the Right Shipping Boxes for Your Business Needs?

-

2026 Best Personalized Shipping Boxes for Your Business Needs?